Sustainability

Generating a combined impact around environmental, economic performance and engagement

We are committed to act for a sustainable future and contribute to carbon neutrality by 2030. We strive to find the most sustainable solutions for our partners and customers, focusing on optimizing material, energy, and area usage, as well as enhancing quality, effectiveness, and efficiency. To accomplish this, we leverage our extensive background knowledge of products and industrialized solutions.

Our sustainability work is based on three sustainability principles that we call the E3 model. The three E's stand for:

- Engagement (Social sustainability),

- Economics (Financial sustainability)

- Environment (Ecological sustainability).

These 3 pillars are all equally important and make for a rational and balanced approach. It is the incentive for our profitability.

E3 aims to break down silos, reduce complexity to generate greater performance, better contribute to the ecological transition and encourages choices to support collective action.

The key drivers of our E3 model are:

-

Economy: Simplify to amplify

-

Environment: From greenwashing to green acting

-

Engagement: Switch from the simple KPI to the collective passion project

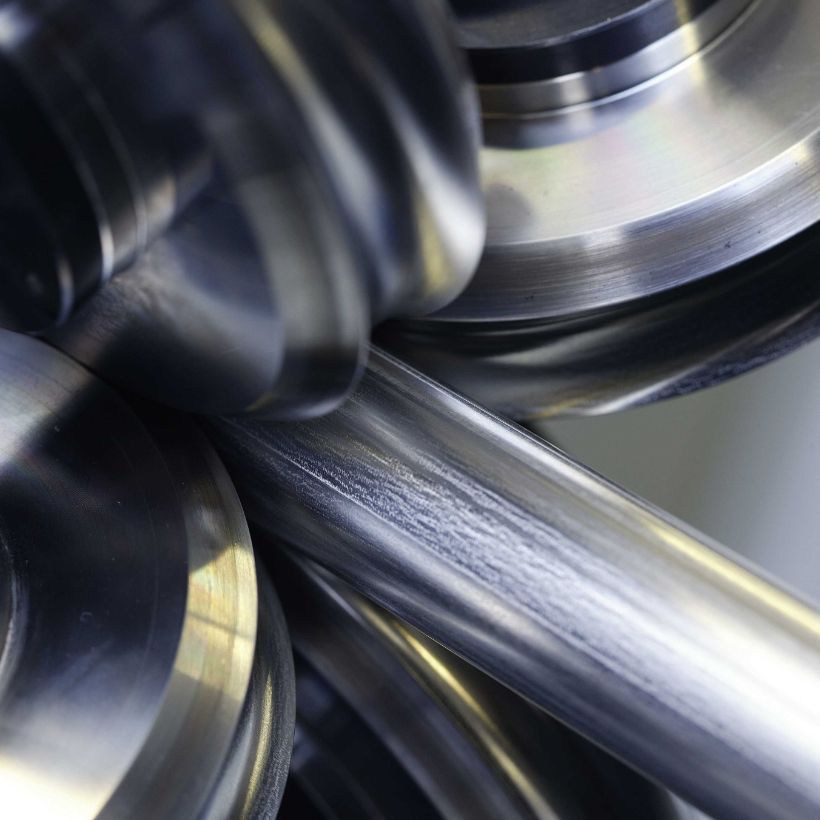

UniWEMA® solutions are designed with full alignment to the E3 performance model not only on the manufacturing side but also for the final user that would benefit from this powerful model when using UniWEMA® solutions.

- Uncompromised safety minimize injury risks with intuitive operations and thoughtfully designed safety features, ensuring peace of mind for your team

- Ergonomic excellence: designed for effortless handling and use, enhancing comfort and productivity in every interaction

- Commitment to sustainability: ensures material circularity by embracing the reduce-reuse-recycle philosophy, minimizing waste, and promoting eco-friendly practices

- Zero waste, maximum efficiency: continuous welding completely eliminates scrap, delivering cost savings and environmental benefits

- Optimized space utilization: eliminates leftover materials on rolls, freeing up storage and maximizing operational efficiency

- Uninterrupted production: enables extended product lengths, maximizing efficiency and throughput

- Minimized downtime: streamlined setup processes significantly reduce delays, boosting productivity

- Lower testing costs & faster results: continuous welding facilitates testing longer product lengths, saving time and resources

- Superior quality, lower costs: automated, high-precision welding reduces non-quality expenses while ensuring consistent excellence

- Simplified supply chain: standardized raw material lengths streamline operations, reducing complexity and optimizing logistics

Our websites

Select your country to find our products and solutions

-

Africa

- Africa

- Ghana

- Ivory Coast

- Morocco

- North West Africa

- Americas

- Asia

- Europe

- Oceania